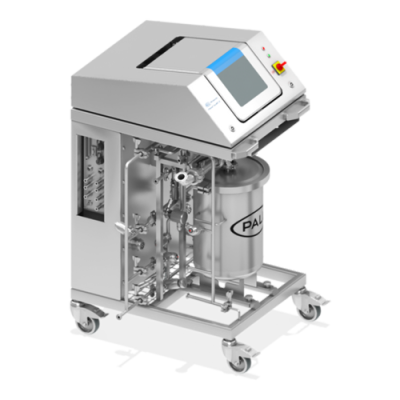

Allegro Connect virus filtration system

Single-use automated filtration system designed to deliver robust process control during this critical downstream step.

产品详情

The Allegro™ Connect Virus Filtration System is a single-use automated filtration system designed to deliver robust process control during this critical downstream step. This next generation compact and elegant system is designed to minimize risk through a fully automated process with recipe-controlled steps, including pre-use manifold leak test, pre-use and post-use filter integrity tests (with the help of an integrated Palltronic® Flowstar IV Filter Integrity Test Instrument), system priming, product filtration and buffer chase, with all data stored in a batch reporting system, significantly reducing non-conformities and manual labor.

- Integrated Palltronic™ Flowstar LGR filter integrity test instrument for in-situ pre-use and post-use integrity testing of virus filters as well as pre-use manifold leak test.

- Configurable recipe-controlled phases to automatically perform pre-use system equilibration, product filtration and buffer chase, with maximum product recovery utilizing standard manifolds

- Smooth transition between filtration and buffer chase phase while keeping the process parameter within the limit to eliminate impact on virus retention from back diffusion during process interruptions

- Wide range of process options to control functions such as flow, differential pressure and inlet pressure, that covers the majority of virus filtration process strategies

- Flexible configuration compatible with all commonly used virus filters

- Easy to install single-use flow path with the shadow board concept and guided human machine interface (HMI) instructions for installation in less than 60 minutes and uninstallation in less than 15 minutes by a single operator

- Batch reporting summary compiling data from the single-use sensors within the flow path, filter integrity testing results, and other critical process parameters.

The Allegro Connect Virus Filtration System utilizes single-use technology (SUT) to ensure faster turnaround between product batches, eliminating the need for clean-in-place (CIP) and sterilization-in-place (SIP) operations and associated cleaning validation, reducing maintenance costs and system downtime, thereby ensuring increased plant productivity.

相关产品

培训课程

收藏

收藏 询价

询价